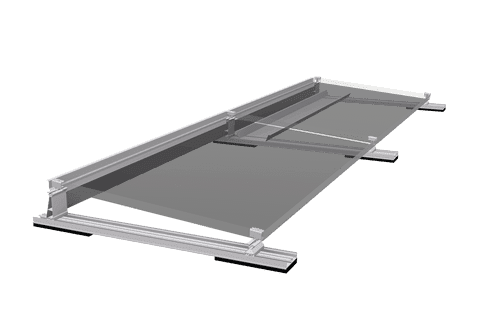

Schletter incremental system

for flat roof

With Schletter incremental system for flat roof, modules can be placed with non-screw clamps (spring clamps) onto the base structure.

SCHLETTER FIXING TECHNIQUE – SUPPORTS BEAM KIT FOR FLAT ROOF

The triangle needed for the installation is completely pre-assembled: they are already assembled in the factory, you just have to bolt it together on site. In case of bigger arrays module lines are placed onto two horizontal profiles and those are placed on single mounting pieces, too. Modules are usually installed vertically. The mounting structure is either can be fastened to the roof or weighed down individually.

LIGHT TRIANGLE

Very light profiles especially for cross-directed and vertical installation in case of less wingspan. Normal angle of incidence is 30°, arbitrary angle can be ordered.

The manufacturer provides 25 years of overall warranty for every Schletter mounting product.

Why to choose Schletter products?

OUTSTANDING PRICE/VALUE RATIO Long life expectancy, flexibility, loadability

RELIABLE More than 20 years of experience in solar mounting system production. Recognised, german manufacturer with international mindset.

CUSTOMER-ORIENTED Stock in Hungary. Frequent trainings, technical support.

INTERNATIONAL CERTIFICATIONS ISO 9001:2015, TÜV, ETA, UL, ETN.

CONFIGURATION User-friendly configurator software. Schletter configurator 2.0/3.0

FAVORABLE WARRANTY Product warranty: 25 years

SCHLETTER CONFIGURATOR 3.0

The renewed Schletter configurator now uses Google Maps to make configuration even more effective.

You can install the application using the guide by clicking on the link below.

Installation video guideDo you have questions?

If you are interested in our current price list, don’t hesitate to contact us! Our expert colleagues will help you, whether it is a technical question or product availability.

Contact us at +36 70 598 5607 or email export@wagnersolar.hu

Product details

Material and instrument-optimized system that enables modules to be installed in closed rows and with 6 to 13 degrees of angles under minimal load. The components are attached to each other with a click-in technology. Modules can be placed with non-screw clamps (spring clamps) onto the base structure. This way modules are fixed at their outside edges.

Made in Germany